|

|

|

Laminated Elastomeric Bearing

|

|

To Contact Us

Tele: + 971 50 6268246

Fax: + 971 6 534 7707

....please copy and

paste this email id...

pretread@eim.ae

Site Translation

Neoprene is Registered Trademark of DupontDow

|

|

|

|

|

|

|

|

Bridge Bearings

Neoprene Bearing Pads,neoprene bridge bearings, laminated

elastomeric bearings,seismic isolators etc are generally known as

bridge bearing pads in Construction industry. We manufacture them

in our purpose built plant using high-grade virgin Neoprene -

Polychloroprene Grade- 2 elastomer- mixed with carbon black and

rubber chemicals to form into a rubber compound to match AASHTO M

251 Specification under controlled heat and pressure.

In house Quick Production Test of all bearings shall be done

at Clients/Representative presence. Tests confirming to AASHTO

specification in accordance with Acceptance Testing on either

Level I or Level II or Short/Long-Duration Compression Test up to

4200 kN with horizontal shear up to 400kN can be carried out in

our facility.

Why Laminated Neoprene Elastomeric Bridge bearings?

Neoprene bridge bearings - plain or laminated - elastomeric

bearings are much easier to install in a bridge than compared to

other types of bearing used and require nil maintenance. Unlike

most other elastomer, Neoprene rubber under-goes no marked

stiffening at low temperature when the thermal contraction of the

bridge deck is at maximum. Such stiffening could be deleterious

to bearing and / or structure. Correctly-designed and

suitably-compounded laminated Neoprene Rubber bridge bearings can

be confidently expected to function efficiently for at least a

decade.

Advantages of Neoprene Elastomeric bearings.

As efficient bearing plates for pre-cast, pre-stressed

concrete or steel beams in bridges and buildings, Neoprene Pads -

plain and laminated - manufactured by us permits a smooth and

uniform transfer of load from the beam to the substructure and

allow beam rotation at the bearing due to deflect ion of the beam

under load. They further allow lateral and longitudinal movement

of the beam caused by thermal forces. Neoprene Pads have no

movable parts and thermal expansion and contraction are absorbed

by the pad's ability to give and take in shear. There is no

sliding motion between pad and beam or between pad and

abutment.

Neoprene bridge bearing specifications.

The material specifications for the elastomeric bearing shall

meet all the current requirements of AASHTOM M 251.Bearing pads

and elastomeric bearings will comply with Articles 18.2.3 through

18.2.6 of Section 18, Bearing Devices, Division II, Construction,

of the AASHTO Standard Specifications for Highway Bridges.

Bearing pads and laminated bearings shall be of the compound

known as neoprene and shall be cast in molds under pressure and

heat. A plain elastomeric bearing pad and steel load distribution

plate combination shall be classified as a laminated elastomeric

bearing. Test specimens shall be in accordance with ASTM D 3182

or D 3183. Where test specimens are cut from the finished

product, a 20 percent variation from the original physical

properties is allowed.

Catalogue- Laminated Bearings.

Please download our coloured catalogue on Laminated Bearings

in pdf format

|

Testing - Laminated Bearing.

Laminated Elastomeric Bearing Tesing.Please click to

visit

|

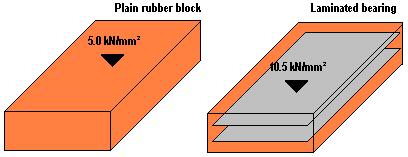

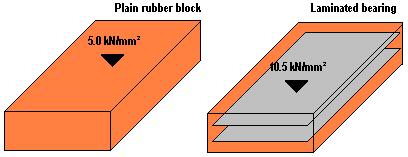

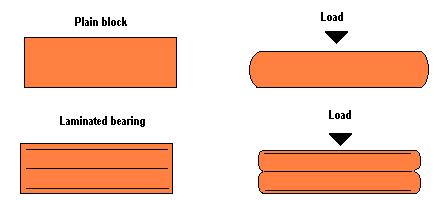

Difference between a plain rubber block and laminated

elastomeric bearings

The capability of plain rubber block to carry vertical load

increases as the number of laminations..mild steel shims

increases.

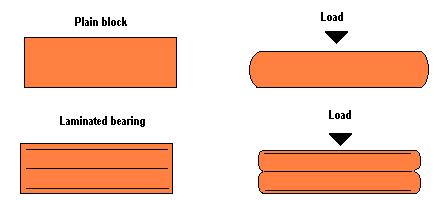

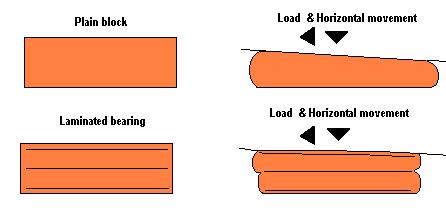

How a plain rubber block and laminated bearing reacts against

vertical load.

Plain rubber block under vertical load compressed down where

as a laminated bearing bulge out with each laminations absorbing

most of the vertical load.

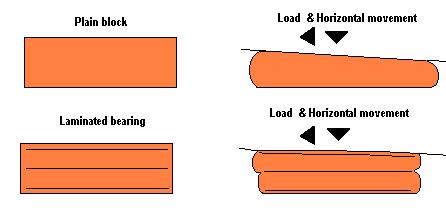

How a plain rubber block and laminated bearing reacts against

horizontal load.

Manufacturing procedure - Compression moulding:

Elastomeric bearings shall be composed of multiple laminate

of elastomeric material separated by steel reinforcing. The

overall size of the bearing, the number of laminate and thickness

of laminate are designed in accordance to the requirement of Load

to be Transferred. Bearings having steel plates as reinforcement

shall be cast/compression moulded/vulcanized as a single unit in

a mould under pressure and heat.

Internal Laminate

Internal plates shall be ASTM A 36/A 36M or A 570/A 570M,

Grade 36 or Grade 40. All plates shall be deburred. The internal

plates shall not be less than 1.88 mm (0.074 inch) thick.The

steel plates separating the elastomeric layers will be completely

bonded by vulcanization to the elastomeric material on all

surfaces using special metal to rubber bonding adhesive. All

external load bearing steel plate(s) if present, shall be factory

vulcanized to the elastomeric bearings during the primary molding

process.

Bearing Acceptance Tests

Acceptance Tests of the pads and bearings shall be according

to Level I acceptance criteria of Article 18.2.5. This testing

shall be included in the price bid for the bearings.

Mechanical Bridge Bearings.

Mechanical bearings are also manufactured and supplied by us

and further investments for plant up-gradation is under

way.Please send us your requirement for Pot Bearings

Testing of Neoprene Bridge Bearings

In house Quick Production Test of all bearings shall be done

at Clients/Representative presence. Tests confirming to AASHTO

specification in accordance with Acceptance Testing on either

Level I or Level II or Short/Long-Duration Compression Test up to

4200 kN with horizontal shear up to 400kN can be carried out in

our facility. More details and pictures are avaialble from

following link.. Laminated

Elastomeric Bearing Testing.

BS 5400 - with Natural Rubber.

Natural Rubber Compounds are used where Laminated Elastomeric

bearings are designed, manufactured and tested in accordance to

requirements with BS 5400 Part 9.

So at www.pretread.com you have your single relayable source

for all your requirements of sliding bearing,expansion joints

neoprene pads, manufactured from polychloroprene. Even for

building bearings, expansion joints, elastomeric bearings, shock

absorber mountings,and custom bridge bearings, manufactured to

your specification, with approval from American Association of

State Highway and Transportation Officials. Our PTFE laminated

elastomeric bearings,bridge bearings, isolation pads,seismic

isolators, and pot bearings are manufactured complying to US road

transportation authority specifications.

Please browse through our web site for more information and

contact us for further details and inquires for neoprene bridge

bearings,bridge bearing, bearing pads,seismic isolators,

laminated elastomeric bearings, precure tread rubber, retread

equipments, moulded rubber products molded rubber,rubber

products.

High Damping Rubber Bearing (HDRB)

High Damping Rubber Bearing (HDRB) - as an alternative to the

lead rubber bearing. We offer high damping rubber bearing

which is ideal for seismic isolation with one device - supporting

the structure, providing the elastic restoring force and also the

required amount of damping up to a maximum of 10-15% of critical.

High Damping rubber bearing are most advantageous when the

movements encountered are not large and there is room for the

increased height of the bearing. Moderate damping is achieved

with this type of the bearing.

Lead Rubber Bearings

A lead rubber bearing a bigger laminated bearing manufactured from layers of rubber, sandwiched together with layers of steel, except for that in middle of bearing there will be a solid lead "plug." Top and bottom of the bearing is fitted with steel plates, which are used to attach bearing to building through its foundation.

These lead rubber bearings are designed in such a way that bearing is very stiff and strong in vertical direction, but flexible in horizontal direction. Lead, inserted as center core of bearing dissipates the energy of earthquake while the rubber, reinforced with steel plates, provides stability, supports structure and isolates vibrations.

Bearing Load Calculations

Let us verify load calculations for your bearings. Send us

sizes, construction and load details of your bearings and we will

send results on design parameters compared to AASHTO LRFD.

To View: a sample page in .pdf on bearing deigning

calculations

Click to see sample

Sizes of Plain and Laminated Elastomeric Bearings

manufactured by us.

Let us help you to design your requirements of elastomeric

bearings. Please click on the links to

visit our form fill up page and we can design bearings to

your requirement

Disclaimer.

The data and commentary contained within this website is for general information purposes only. It is provided without warranty of any kind. www.pretread.com shall not be held responsible for any errors, omissions, or misuse of any of the enclosed information and hereby disclaims any and all liability resulting from the ability or inability to use the information contained herein. Anyone making use of this material does so at his or her risk. In no event will www.pretread.com. be held liable for any damages including lost profits, lost savings, or other incidental or consequential damages arriving from the use or inability to use the information contained within. www.pretread.com suggests contacting to contact us for suitability for a particular application in rubber products.

|

Thank you very much for visiting us.

|

|

Bearing Load Testing.

We are the first and only laminated bearing manufacturing

facility in Middle East to have an in-house bearing testing

facility to carry out tests confirming to AASHTO

specification in accordance with Acceptance Testing on either

Level I or Level II as well as Short/Long-Duration Compression

Test. Our bearing testing machine can test bearings to Vertical load of 4200

kN with horizontal shear load up to 400kN and movement to 100

mm.

|

Bearing Load Calculations

Let us verify ..load

calculations.. for your bearings. On receipt of corbel

size, and load details of your requirements, and we can provide

calculations and bearings sizes based on results on design

parameters compared to AASHTO LRFD - FREE.

|

|

|

Dealer-ship

Dealer ship and agency offered, please contact us with

details on your organization,current activities and area of

interest.Send us an email to:

pretread@eim.ae

|

Bearing Design

Let us help you to design your requirement of

elastomeric bearings click on the links to visit Design a Bearing

Form- - we can support you to design elastomeric bearings to

requirement

|

Picture Gallery

Installed Bridge Bearing

|

|